Thermic welders

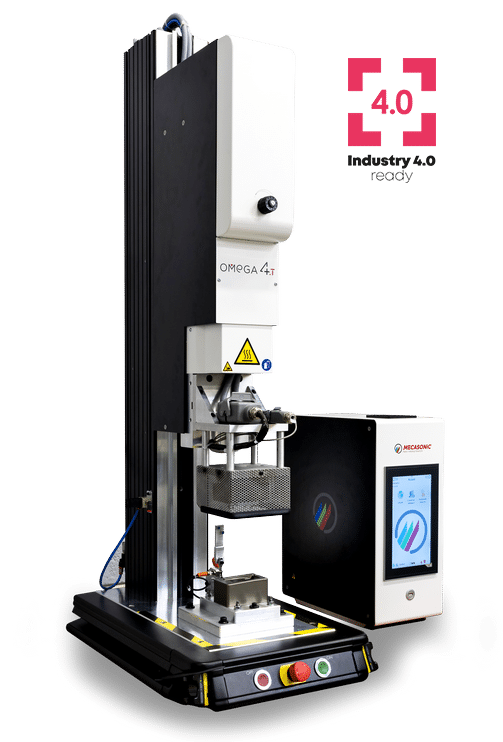

Thermic welder Omega 4.T

_

The thermic welder Omega 4 T assembles with reliability thermoplastics. The device meets criteria of Industry 4.0

It is available on different versions, on table,on sole plate or module for integration, in soundproof cabin and as a workstation.

Description

It offers you:

Productive intelligence : start-up self-checks, warnings if the machine runs out of air, part melting detection, production monitoring specifying the part welding status.

High connectivity: ethernet, OPC UA server, VNC remote access, USB port

Touch HMI Human Machine Interface: to easily and quickly program welding settings with built-in assistance.

Characteristics

- As standard, interfacing with operator’s PLC via SubD-37 connection (binary I/O)

- A colour touchscreen with a user-friendly, multilingual interface for configuring settings and monitoring production

- 2 welding modes (Time and Distance)

- 12 programmable welding steps

- Good part control window

- Control windows precision: 0.01 mm, 0.01 s

- Multi-lingual menu system

- Built-in multilingual assistance and summary images

- Dedicated safety PLC

- Dedicated safety PLC

- Ethernet connectivity for remote control

- 2 user USB ports for exporting curves, results, and settings

- Start-up check-in

- Two-handed control with dual encoder

Uses

- Medical

- Automotive

- Households

- Packaging

- Cosmetics

- Other